High Performance HMI Interface design

High Performance HMI (HP-HMI) is an approach to designing user interfaces for the control and monitoring of industrial processes, aimed at helping operators make the best possible decisions in the shortest time.

These interfaces often appear simple and dull, even to the point of being monotonous, earning them the nickname “gray screens”. Operators might initially dislike them due to the lack of vivid colors and animated elements like burner flames they are accustomed to. However, once they realize that they can calmly read newspapers and only need to glance at the screens every 10 minutes, their opinion changes dramatically.

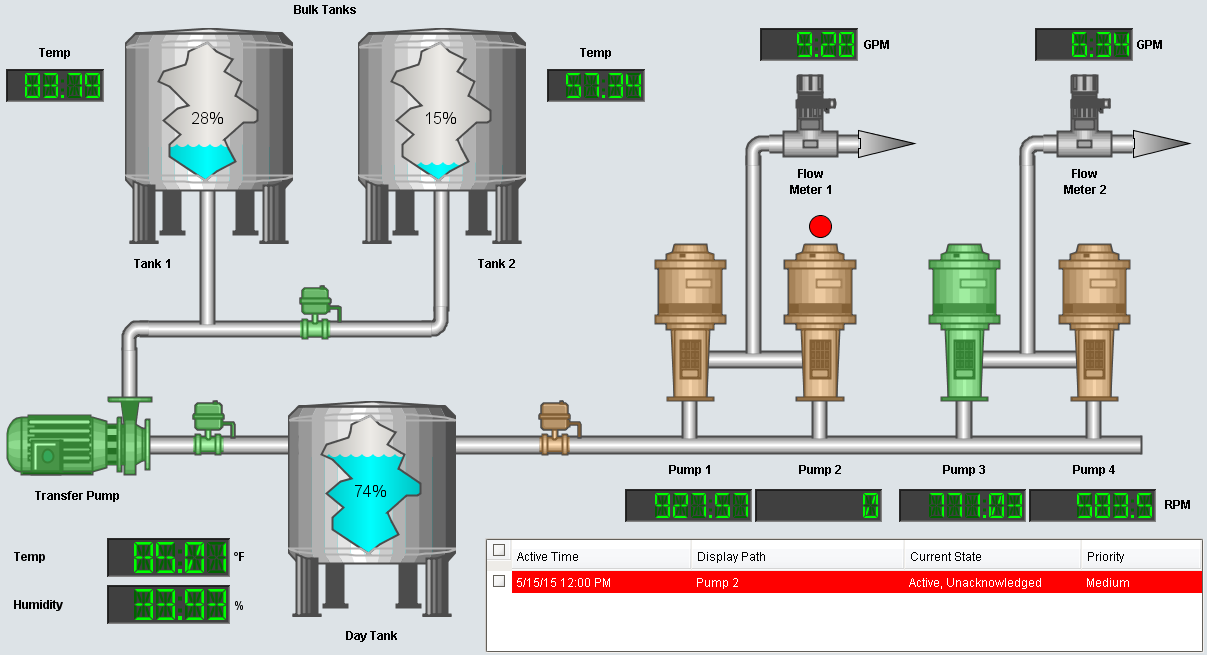

One of the fundamental principles is that normal conditions are displayed in a muted gray, while problematic conditions are shown in bold, vivid colors. This allows operators to instantly determine if they need to take action—if they see a bold color, they act; if everything is gray, they continue their tasks.

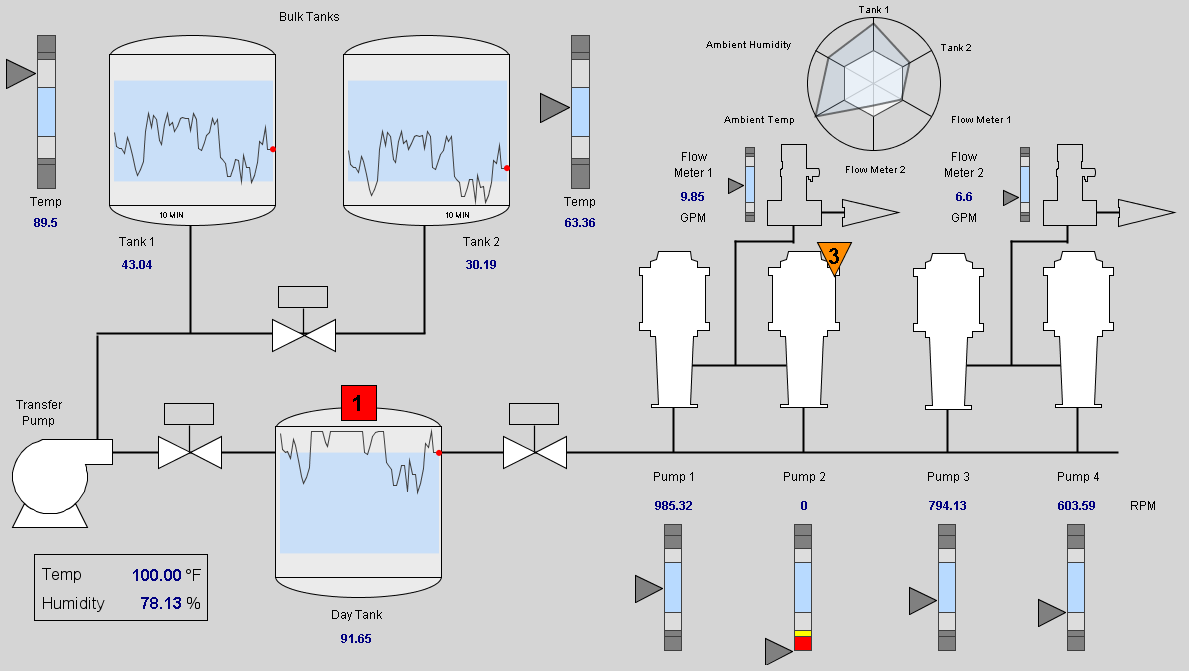

For example, a traditional depiction of a manufacturing process may attempt to capture the physical appearance of the operation, but this can detract from the operator’s focus. Every glance at the screen requires them to evaluate whether everything is functioning correctly or if action is needed, which is not immediately obvious:

In contrast, adhering to High Performance HMI principles means focusing not on the appearance of the technology, but on ensuring that operators can instantly see when action is required—when something is lit or flashing. It also provides context for the data—operators can see not just the current level in a tank, but its historical trend, and whether the level is rising or falling:

These and many other principles are detailed in the ISA101 standard—Human Machine Interface, which is in the process of being transformed into the new IEC standard IEC63303—Human-Machine Interface for Process Automation Systems.

Portfolio

- SCADA/MES – Production Process Management

- Industrial IoT – Data Collection and Analysis

- Building and Data Center Monitoring

- Predictive Maintenance and OEE Monitoring

- Digitalization/Optimization of Manufacturing Processes

- Reporting and Business Intelligence

- High Performance HMI Interface design

- Energy Consumption Monitoring

- Connecting Enterprise Systems, Databases and SAP ERP

- Consulting / Advisory