Energy Consumption Monitoring

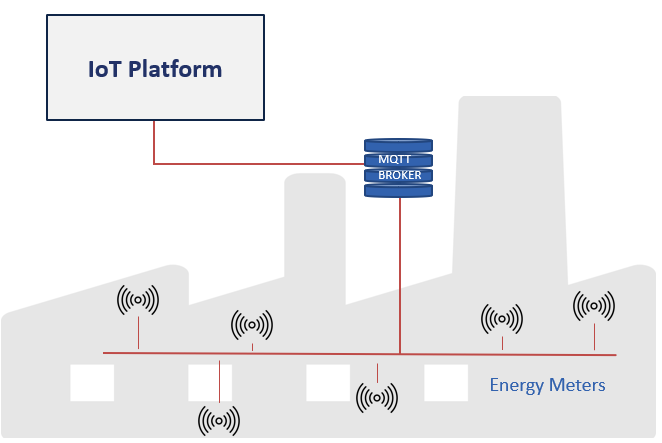

An Energy Management System (EMS) is an essential component for effectively managing energy consumption across various industrial sectors. Its primary goal is to provide an accurate overview of electricity, water, gas, heat, and other resource usage. To achieve this, various types of consumption meters, such as electricity meters, water meters, and gas meters, are integrated into the EMS system via communication modules.

The first step in implementing an EMS system is to identify all relevant consumption meters within the organization. This is followed by selecting and installing IIoT modules for these meters. These modules convert, collect, and transmit data to a central system, where it is stored historically and processed. Users then have immediate access to this data through real-time dashboards, graphs, and reports.

The first step in implementing an EMS system is to identify all relevant consumption meters within the organization. This is followed by selecting and installing IIoT modules for these meters. These modules convert, collect, and transmit data to a central system, where it is stored historically and processed. Users then have immediate access to this data through real-time dashboards, graphs, and reports.

An EMS system offers numerous advantages to businesses. In addition to monitoring consumption, it helps identify opportunities for reducing energy use. This way, businesses can achieve energy savings and lower their costs. The EMS system can be implemented at various levels, whether at the enterprise level, within production halls, or even specific technological units, depending on the customer’s requirements and needs.

With the help of an EMS system, businesses can manage more efficiently, minimize energy losses, and contribute to environmental sustainability through better energy utilization. It is a tool that aids modern enterprises in achieving their energy management goals while also supporting a sustainable future.

Portfolio

- SCADA/MES – Production Process Management

- Industrial IoT – Data Collection and Analysis

- Building and Data Center Monitoring

- Predictive Maintenance and OEE Monitoring

- Digitalization/Optimization of Manufacturing Processes

- Reporting and Business Intelligence

- High Performance HMI Interface design

- Energy Consumption Monitoring

- Connecting Enterprise Systems, Databases and SAP ERP

- Consulting / Advisory